Computer numerical control machining sits at the center of modern manufacturing. If you look around—cars, phones, medical devices, aircraft parts—most of those components were shaped, cut, or finished using CNC machines. What once required manual skill and long setup times now runs through code, precision motors, and repeatable processes.

This blog explains computer numerical control machining in depth, without textbook stiffness. You’ll learn what CNC machining technology is, how it works, the machines involved, the roles of operators and programmers, salary expectations, machine prices, and why CNC turning centers and machining centers dominate today’s factories.

What Is Computer Numerical Control Machining

Computer numerical control machining, often shortened to CNC machining, is a manufacturing process where machine tools are controlled by a computer program. Instead of moving tools by hand, instructions are written in code and executed automatically.

The machine follows those instructions with high accuracy, cutting material into precise shapes again and again with minimal variation.

At its core, CNC machining converts a digital design into a physical part.

also read : – SLS Lifestyle: What It Really Is, How It Works, and Whether It’s Worth It

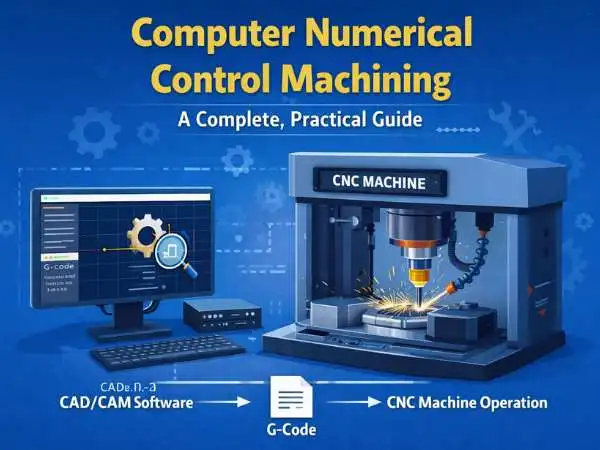

How Computer Numerical Control Machining Works

The CNC process follows a clear chain from idea to finished part.

First, a part is designed using CAD software. That design is then converted into machining instructions using CAM software. These instructions are written in a language the machine understands, usually G-code.

Once the program is loaded:

- the machine positions the tool

- material is cut or shaped

- movements follow exact coordinates

- the same result repeats every cycle

Human involvement shifts from hands-on cutting to setup, monitoring, and quality checks.

Computer Numerical Control Machining Technology Explained

Computer numerical control machining technology combines mechanical systems, electronics, and software. Each part of the system plays a role.

Key elements include:

- a computer controller

- servo motors or stepper motors

- machine tool structure

- cutting tools

- feedback systems

Together, these elements allow precise motion along multiple axes.

Modern CNC technology supports complex shapes that would be nearly impossible by hand.

Evolution of CNC Machining Technology

CNC machining grew out of numerical control systems developed in the mid-20th century. Early machines used punched tape. Programs were difficult to modify and limited in complexity.

As computers improved:

- programs became editable

- memory increased

- accuracy improved

- automation expanded

Today’s CNC machines integrate sensors, networking, and simulation tools.

Types of Computer Numerical Control Machine Tools

CNC machine tools come in many forms, each designed for specific tasks.

CNC Milling Machines

CNC milling machines remove material using rotating cutting tools. They are widely used for flat surfaces, slots, pockets, and complex 3D shapes.

Multi-axis milling machines can move the tool and workpiece in several directions at once.

CNC Turning Machines

CNC turning machines rotate the workpiece while a stationary tool removes material. These machines excel at producing cylindrical parts.

They are common in automotive, aerospace, and industrial component manufacturing.

CNC Drilling and Boring Machines

These machines specialize in creating precise holes and internal features. While drilling can be part of milling, dedicated machines handle high-volume hole operations efficiently.

CNC Grinding Machines

Grinding machines remove very small amounts of material for fine finishes and tight tolerances. They are often used in tool making and precision engineering.

also read : – Opera GX: The Gamer-Focused Browser Explained (PC, Mobile APK, Features & FAQs)

Computer Numerical Control Machining and Turning Centers

Computer numerical control machining and turning centers represent a more advanced class of machines.

A machining center typically includes:

- automatic tool changers

- enclosed work areas

- multiple axes of motion

Turning centers expand on basic lathes by adding live tooling, allowing milling and drilling on a rotating part.

These machines reduce setup time and improve productivity by combining operations.

CNC Machining Centers vs Conventional Machines

Compared to conventional machines, CNC machining centers offer:

- higher accuracy

- faster production

- consistent quality

- lower scrap rates

Conventional machines still have value for simple tasks, but CNC dominates when precision and repeatability matter.

Computer Numerical Control Machine Operator

A computer numerical control machine operator runs CNC machines during production. This role focuses on execution rather than programming.

Operators typically:

- load raw materials

- start machining cycles

- monitor tool wear

- check part dimensions

- handle basic troubleshooting

Attention to detail matters more than coding skills at this level.

Skills Required for CNC Machine Operators

Successful operators understand:

- machine safety

- basic blueprint reading

- measurement tools

- machine controls

With experience, many operators move into setup or programming roles.

also read : – How to Reduce Windows’ High CPU Usage? Know How to Apply Them by Reading the Blog

Computer Numerical Control Machine Operator Salary

Computer numerical control machine operator salary varies by region, experience, and industry.

Entry-level operators earn modest wages. Experienced operators working with advanced machines or tight tolerances earn more.

Factors affecting salary include:

- type of machine

- industry sector

- shift schedules

- certification

Demand remains steady due to ongoing manufacturing needs.

Computer Numerical Control Machine Programmer

A computer numerical control machine programmer creates the instructions that control CNC machines. This role sits closer to engineering and design.

Programmers:

- interpret drawings

- select tools and cutting paths

- write or generate G-code

- optimize cycle times

Their work directly affects quality, speed, and cost.

Skills Needed for CNC Programmers

CNC programmers need:

- strong understanding of machining processes

- knowledge of CAD/CAM software

- problem-solving ability

- attention to tolerance and surface finish

Programming mistakes can damage tools or scrap expensive parts, so accuracy matters.

Computer Numerical Control Machining Technology Salary

Computer numerical control machining technology salary depends heavily on role and expertise.

Programmers and setup technicians earn more than basic operators. Engineers specializing in CNC systems earn even higher pay.

Advanced skills in multi-axis machining, automation, or high-precision industries increase earning potential.

also read : – Cutting Edge Apps For Animated Videos

Training and Education for CNC Careers

Many CNC professionals start through:

- technical institutes

- vocational programs

- apprenticeships

Hands-on training matters more than theory alone. Many skills develop directly on the shop floor.

Continuous learning stays important as machines evolve.

Computer Numerical Control Machine Price

Computer numerical control machine price ranges widely depending on type and capability.

Basic CNC machines may cost:

- tens of thousands of dollars

Advanced machining centers may cost:

- hundreds of thousands

- or even millions

Price factors include:

- number of axes

- automation features

- brand reputation

- software integration

Maintenance and tooling costs add to long-term investment.

Why CNC Machines Cost So Much

CNC machines combine precision mechanics, electronics, and software. Tolerances are tight. Components must withstand stress, heat, and vibration.

Reliability matters because downtime costs money.

High upfront cost often pays off through productivity and reduced waste.

Industries That Depend on CNC Machining

CNC machining supports many industries.

Key sectors include:

- automotive

- aerospace

- medical devices

- electronics

- energy

- defense

Each sector demands different materials, tolerances, and quality standards.

Materials Used in CNC Machining

CNC machines work with a wide range of materials.

Common materials include:

- aluminum

- steel

- stainless steel

- brass

- titanium

- plastics

Material choice affects tooling, speed, and cost.

also read : – Detailed Login and Other Details of MIS webmail

Precision and Tolerances in CNC Machining

CNC machining achieves tight tolerances consistently. Machines can repeat movements within microns.

Precision matters for:

- interchangeable parts

- safety-critical components

- high-performance systems

This consistency drives CNC adoption worldwide.

Automation and CNC Machining

Modern CNC shops integrate automation.

Examples include:

- robotic loading systems

- pallet changers

- unattended night shifts

Automation increases output without increasing labor hours.

CNC Machining vs Other Manufacturing Methods

Compared to casting or molding, CNC machining offers:

- higher accuracy

- better surface finish

- flexibility for small batches

However, CNC machining costs more per part for high-volume production.

Manufacturers choose methods based on volume, cost, and design needs.

Quality Control in CNC Machining

Quality control ensures parts meet specifications.

Methods include:

- in-process measurement

- coordinate measuring machines

- visual inspection

CNC machines reduce variation, making quality easier to maintain.

Safety in CNC Machining

Safety remains critical.

Operators must:

- follow lockout procedures

- wear protective gear

- understand emergency stops

Modern machines include enclosures and sensors to reduce risk.

Challenges in CNC Machining

Despite its advantages, CNC machining faces challenges.

Common issues include:

- skilled labor shortages

- high equipment cost

- tool wear management

Ongoing training and maintenance help address these issues.

Future of Computer Numerical Control Machining

CNC machining continues to evolve.

Trends include:

- smarter machines

- better simulation

- integration with digital factories

CNC remains central even as additive manufacturing grows.

Why Computer Numerical Control Machining Still Matters

Despite new technologies, CNC machining remains unmatched for precision, strength, and material variety.

It turns digital ideas into reliable physical parts at scale.

That role will not disappear.

also read : – How to Reduce Windows’ High CPU Usage? Know How to Apply Them by Reading the Blog

Final Thoughts on Computer Numerical Control Machining

Computer numerical control machining forms the backbone of modern manufacturing. From simple components to complex systems, CNC machines deliver accuracy, consistency, and efficiency. Understanding CNC technology, roles, salaries, and machine costs provides a clear picture of why this field continues to grow.

Whether you’re studying manufacturing, planning a career, or investing in equipment, CNC machining remains a foundational skill and technology.

FAQs: Computer Numerical Control Machining

What is computer numerical control machining

It is a manufacturing process where machine tools are controlled by computer programs.

What is computer numerical control machining technology

It combines software, electronics, and precision mechanics to automate machining.

What does a CNC machine operator do

They run machines, monitor production, and inspect parts.

How much does a CNC machine cost

Prices range from tens of thousands to millions, depending on capability.

What is a CNC turning center

A machine that performs turning and additional operations in one setup.

Is CNC machining a good career

Yes. Skilled operators and programmers remain in steady demand.