Josh Russell is a project manager at AST’s Life Science. The expert has been advocating for the expansion and growth of aseptic processing using robot technology. The expert argues that the use of robotics will bring about total customer satisfaction. He says that aseptic production has lots of repetitive activities which will require more accuracy and a high volume of reproducibility.

The expert says that robots are better placed to carry out aseptic processing as they can easily perform repeatable operations and be highly accurate. The non-organic automations can perform duties that no human is able to. They will also work better in human-possible environments and much faster.

Steriline is one company that makes good use of robotics in the pharmaceutical industry. It is a leading company in Europe that aims at producing the best injectable products for aseptic processing. The firm was started in 1989 and currently operates in over 50 countries. With an immense focus on collaborative partnership and advanced engineering, the company looks to deliver world-class machines to customers.

There is a growing demand for consistent quality, improved efficiency and enhanced safety which is Steriline’s number one priority. Steriline looks to become the number one choice for aseptic processing manufacturer.

Robotics are quite effective in areas that may seem dangerous to humans. Take for example applications that have potent and highly active compounds. Humans would have a hard time working with the compounds but robots will perform the task to perfection. Robots do not shed any clouds of particulates like humans since there are no viable particulates. As for the non-viable particulates, they generate them at very low levels which means these machines are perfect for ISO5 environments.

Remarkable Robotics Manufacture

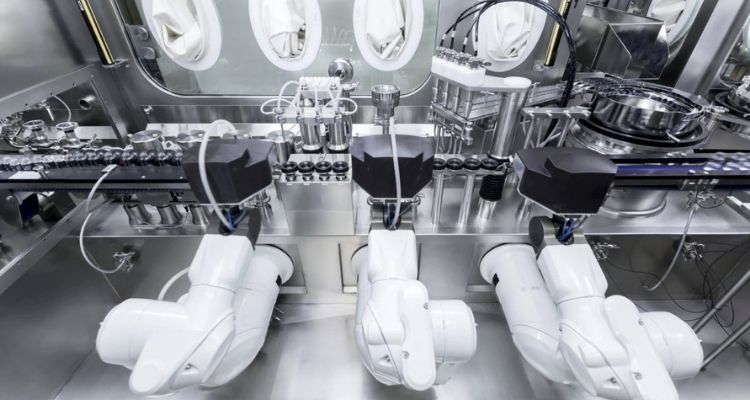

Robots have proved to bring a lot to the table in terms of solutions in the pharmaceutical industry. Staubli robots for example have a line that has six axis robotic arms to perform tasks. The robot is easily compatible with the hydrogen peroxide decontamination vapor phase. With the immense portfolio of the Staubli robot system, providers such as Steriline do not have to alter the payload. That is because these robots are meant to give the optimal solution in the pharmaceutical endeavors.

Suppliers such as Steriline have robots that can complete all the automated tasks needed in aseptic processing according to experts. Today you are likely to find robotic options for almost everything from vial processing to freeze dryer unloading and loading applications to lab automation etc. Most of this commercially available robotics are extremely accurate and well developed. They are equipped with a complex system that involves repetitive maneuvers in picking and placing the glass containers. The robotics will also have a precise positioning of the materials making sure not a single component goes wrong.

That is why robotics are gaining momentum in the pharmaceutical industry. It seems every firm wants to work with robotics. For example, robotics are more effective in manipulating the cartridges and syringes. They have several advantages over the traditional filling lines.

Steriline’s Robotics

As Steriline aims at achieving the top spot in the pharmaceutical industry arena, it looks to give the customers the best quality machines and robotics they can ever ask for. That is why the company specializes in the production of high-quality robotics that are quite efficient. Here are some of the excellent robotics manufactured by the company.

Robotic External Decontamination Machine

It is a decontamination machine that works at a rate of three pieces per hour. The machine has a minimum downtime meaning it is quite efficient. It works with a SCARA Denso robot. With this machine you are also sure to get an inactivation agent washing option. The robot is in complete compliance with the statutory requirements of GAMP and cGMP.

Robotic Tray Loader

This tray loader has a capacity of about 36 pieces for every hour. With this machine there is quick changeover meaning it is quite fast. The robot is designed for cartridges packing and sealed vials. With an automatic vial positioning, the tray loader has a pre-set pattern and follows a certain routine to ensure all the rows are filled up and in a timely fashion. That ensures no waste occurs during the loading process.

The tray uses a SCARA robot which works simultaneously to ensure the vials are loaded correctly one tray after the other. This robot also conforms with the GAMP requirements meaning it is safe for use in the specified environments.

Robotic Tub Decontamination System

It is a tub decontamination robot that works on approximately two tubs every minute. This robotic will decontaminate any kind of tub you have while decontaminating trays at the same time. There is no format change with this robot and it is designed to clean tubs before they get to the de-linerstation.

Robotics have already proved to be quite helpful in aseptic processing. That is why Steriline is on the line to manufacture high quality robotic machines to assist with the processing of pharmaceutical products. Robots will perform the tasks at a faster rate than humans can, which makes them a preferable choice to many pharmaceutical companies.